Design

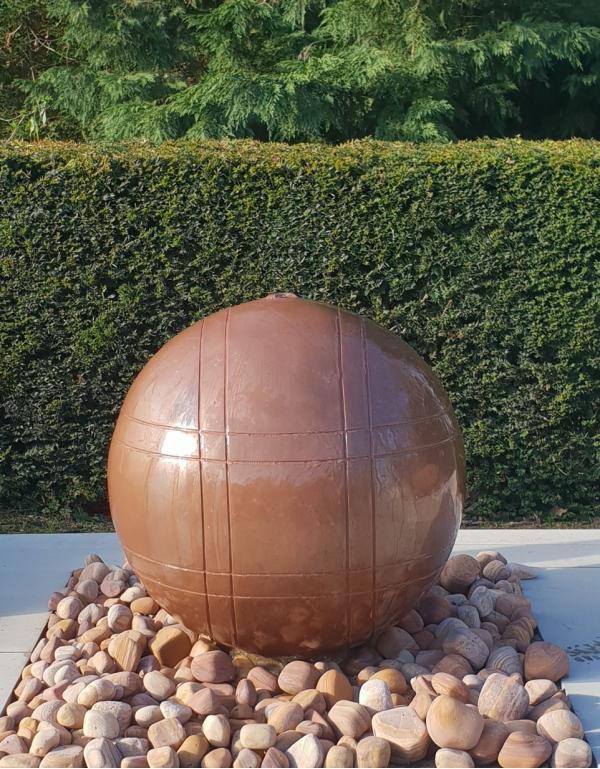

The design phase focused on two key performance criteria. First, replicating the rich, genuine aesthetic of solid metal using our liquid metal finishes applied to a lighter substrate. Second, ensuring the surface finish was entirely functional and durable in an outdoor environment, specifically guaranteeing that the coating would stand up successfully to the erosive effects of chlorinated water typical in many water feature systems. This required a finish formulation that was both aesthetically perfect and chemically resilient.

Make

The technical aim was to successfully reproduce a version of the heavier, traditional product that could be easily lifted and positioned by a small team, solving the client’s logistical barrier. By applying our specialised liquid metals to a lightweight, custom-fabricated core, we achieved the required authentic metal look while dramatically reducing the overall mass. The key to the process was the expert application of the finish to create a seamless, non-porous surface that could withstand constant water exposure and temperature fluctuations.

Reveal

The finished features were delivered with stunning high polished Copper and Iron finishes, indistinguishable from their solid metal counterparts. Crucially, these features were designed not to remain pristine, but to enhance the authentic aesthetic by being engineered to tarnish and develop a natural patina over time. This reveals the full character of the metal as it ages gracefully, providing the client with a durable, lightweight, high-performance product that tells a story and requires minimal maintenance.