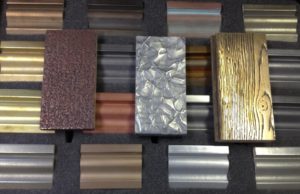

Flexibility of Types of Substrates and Liquid Metal Finishes

Liquid metal finishes transform ordinary surfaces into impressive statements. Perfected by Revelare, this coating is made by mixing real metal powder with specialised binders, creating a sprayable metal veneer that combines the tactile richness of real metal with the versatility of paint.

The most impressive trait of liquid metal is its unparalleled flexibility: it can be applied to an astonishing range of materials and shapes, freeing designers from the usual constraints of solid metal. Liquid metal opens new creative horizons by making almost any substrate look like solid metal without the limitations of weight or cost.

A Metal Finish for Almost Any Material

At Revelare, if we can prime the substrate, we can apply liquid metal to it. Thanks to advanced primers and application techniques, liquid metal can bond to almost any substrate – wood, MDF, plaster, plastics, glass, concrete, ceramics, fibreglass – it’s all possible. Even materials traditionally considered tricky or out of scope can be coated, such as resin, polystyrene foam or acrylic. Below are just some of the applications we can bring to life.

Interiors & Woodwork

Imagine bespoke wooden fixtures – reception desks, wall panels, cabinetry – refinished in liquid metal. The wood provides a workable structure, while the liquid metal surface yields the look of solid metal (bronze, brass, steel, etc.) with far less weight. Designers use this to unify elements in a space with a metallic theme without worrying about the structural or cost challenges of casting large metal pieces.

Plastics & Composites

Many plastics, acrylics or fibreglass forms can be coated. This is beneficial for signage, products and art installations. In fact, the liquid metal technique is so versatile that it is used in industries such as film and set design to make PVC, acrylic or polystyrene props look convincingly like metal. Because the coating is thin, it preserves fine details while adding an authentic metal sheen.

Concrete, Stone & Glass

Architectural materials like concrete or stone can also receive liquid metal overlays, blending the heft of masonry with the luxury of metal. For example, architects can accent a concrete facade with a seamless bronze or copper finish, achieving a modern metallic look on a material that would ordinarily be grey and matte. Glass and ceramic surfaces, when properly primed, can also have a liquid metal finish applied, expanding design possibilities for light fixtures, tiles, and artworks by giving them a striking metal layer.

Indoor to Outdoor

With the right preparation, liquid metal finishes are capable of outdoor application. The coatings are durable and can withstand exterior conditions when applied over suitable substrates and sealed appropriately. Our high-quality liquid metal coatings have been tested to endure 25+ years outdoors without significant degradation, meaning you could coat an exterior wall, door or outdoor sculpture in real metal and expect it to weather just as actual metal would – patinating gracefully or remaining pristine if sealed.

Keep in mind, liquid metal finishes are not superficial paints – they form a bonded metal layer. This gives projects the true metallic qualities designers crave: the play of light on a polished metal coating, the subtle texture of cast metal, and the confidence that comes with a robust finish. Yet, because the metal is only microns thick, it uses only a fraction of the raw material that solid metal would. This efficiency not only makes it cost-effective and lighter, but also more sustainable.

Flowing Curves and Angular Forms: Design Without Limits

One of the most revolutionary aspects of liquid metal finishing is the freedom it offers in terms of shape and form. Because the mixture of metal powder and binder is applied like paint, it conforms to complex geometries and intricate details that would be impractical or impossible to achieve with solid metal. Entire curved reception desks or feature walls can be coated with no visible seams or joints, avoiding the segmentation and welding lines you’d have with sheet metal. Liquid metal essentially eliminates many constraints of traditional metal fabrication, enabling seamless metallic skins on both fluid organic shapes and sharp, angular structures alike.

Our work for Nationwide is an excellent example of our technical expertise. We reimagined a heavy cast-metal fountain sphere to have a lightweight core and sprayed copper finish, achieving the same look and lustre at a fraction of the weight. To learn more, view our Nationwide case study here.

Similarly, in another project, we created a bespoke reception desk finished in a cracked brass liquid metal coating, the cold-spray application allows delicate or angular structures to be coated without warping or seams, yielding a flawless real-metal surface on a design that traditional metalworking would find challenging. The results show that even sharp angles and textured patterns can be achieved with liquid metal finishes. View our bespoke reception desk case study here.

Not only does liquid metal accommodate organic curves, but it also excels on angular and structured surfaces. Sharp corners, geometric patterns, and perforated or lattice designs can all be uniformly coated. Because the application is sprayed and seamless, it can cover internal corners and complex intersections without pooling or unevenness. This makes it ideal for modern designs with faceted shapes or intricate cut-outs. You get a smooth, continuous metal finish over the entire form, rather than having to clad each part separately. See our Ipswich Town Plaque case study to see the details we can achieve.

The lightweight nature of liquid metal coatings means even large installations or elaborate shapes don’t become prohibitively heavy. A dramatic ceiling sculpture or a multi-faceted art piece can be built from light materials and then beautifully metal-coated. Liquid Metal paint is much more practical than trying to fabricate the same form out of solid metal.

In sectors like hospitality and retail design, where visual impact is key, this ability to create show-stopping shapes with liquid metal is incredibly valuable. Liquid metal coatings have been used to produce everything from impressive feature walls to one-of-a-kind furniture pieces, all with the allure of metal but the agility of simpler substrates. In short, whether your design calls for sweeping, fluid curves or crisp, angular lines, liquid metal finishes can fully realise your vision in real metal, without compromise.

Start Your Liquid Metal Finish Project with Revelare

At Revelare, we pride ourselves on meticulous craftsmanship and an innovative approach to surface finishes. Our experienced team of artisans are masters in the art of liquid metal coating, delivering bespoke results that showcase creativity, quality, and reliability. Every project is a collaboration between architects, interior designers and developers to ensure the finish not only meets the brief but elevates it with artistry and enduring value. To explore our catalogue of liquid metal finishes or discuss a bespoke collaboration, get in touch with our dedicated team or request a sample to get a feel for how we can realise your project.